we’re digital marketers who believe strong strategy starts with deep roots

We're Deeply Rooted In:

digital

We offer a critical perspective to know what works, what won't, and what's around the corner.

WHAT WE DOoutcomes

Greatest impact means tying every decision to objectives we outline together.

SEE IT COME TOGETHERa clear path forward

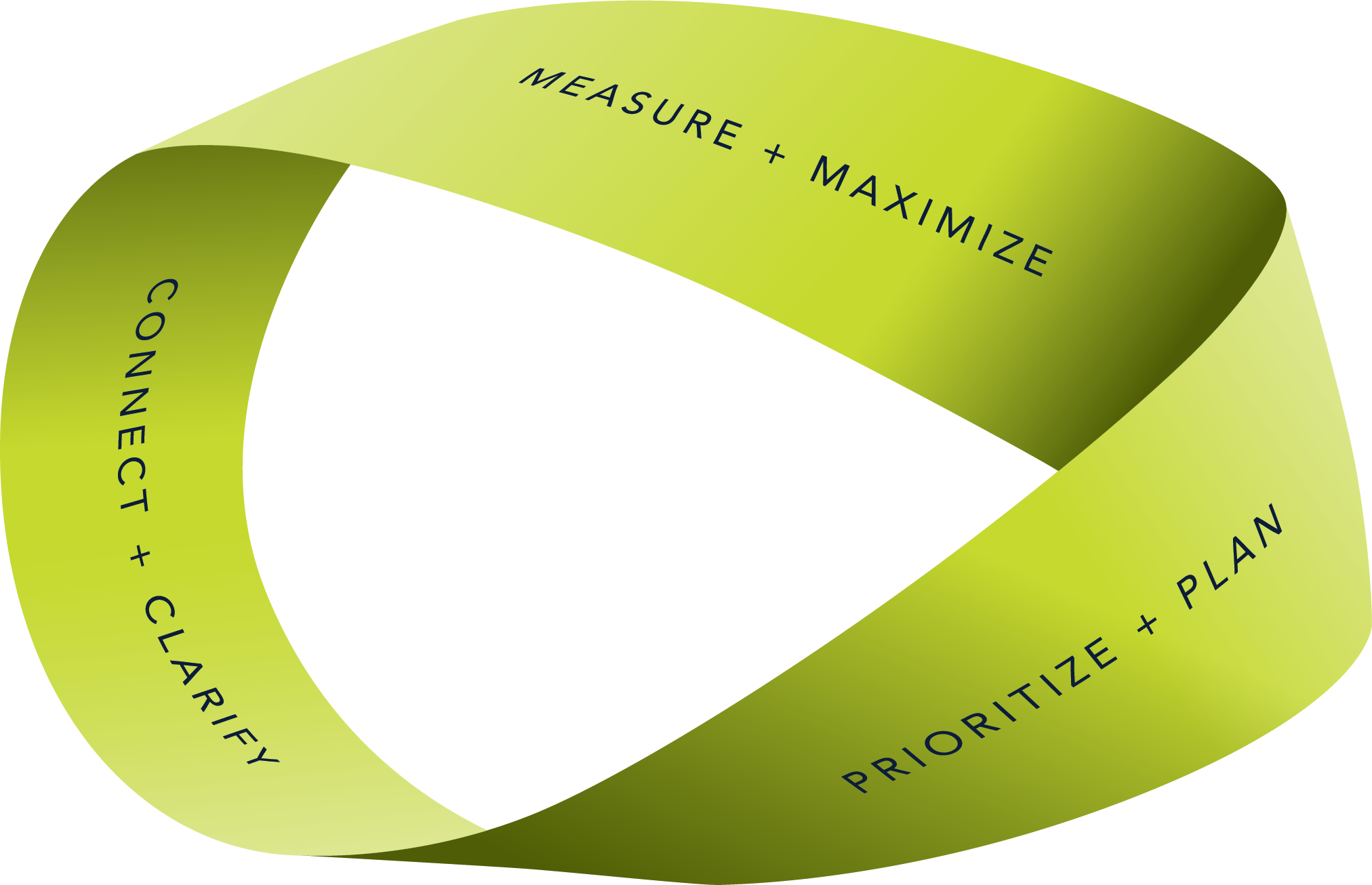

Our goal is to help you amplify the impact of your time and resources. To that end, we will partner with you to set goals, establish strategy, and drive outcomes together. We call this the Fathom Commitment.

Set Goals

Establish Strategy

Drive Outcomes

Our Expertise

digital marketing expertise

You know your business, and you want a partner who knows theirs. Our business is digital marketing, and our expertise spans the following areas.

We optimize your website and content to reach audiences in the ever-evolving search results.

a unique point of view

Our digital marketing specialists provide insight into the challenges we solve and the results we achieve. A critical perspective for you, the marketing leader.

more than measurable results

While we'll continue to evolve to meet the needs of the marketing leader, our commitment to creating an unmatched client experience will never waiver.

It's about you. It's about us. It's about what we'll do together.